It includes direct labor (workers’ pay) and manufacturing overhead (other production expenses). Therefore, one difference between the two concepts is that manufacturing overhead is only included in conversion costs. The other difference is that the cost of direct materials is only included in prime costs. recording transactions Thus, each cost concept provides a somewhat different view of the costs incurred to create products. The conversion of materials into a finished product is what we call “conversion.” It’s an important process that happens at every stage in the manufacturing cycle.

Conversion Cost: How to Calculate and Use It for Cost Accounting and Management

- The inventory valuation is the cost of the goods that are not sold and remain in the ending inventory, and it is reported as a current asset in the balance sheet.

- A positive variance indicates that the actual conversion costs exceeded the budgeted costs, while a negative variance suggests that the actual costs were lower than the budgeted costs.

- Conversion costs include all direct or indirect production costs incurred on activities that convert raw material to finished goods.

- Therefore, one difference between the two concepts is that manufacturing overhead is only included in conversion costs.

- Manufacturing overheads used in calculating conversion costs are the overheads that cannot be attributed to the production process or a single unit in production, for example, rent or electricity.

This information can be useful for cost accounting and management purposes, which we will discuss in the next topics. Pls noted that depreciation expenses, insurance expenses, maintnain expenses and electricity expenses are considered as manufactoruing overhead and we have to include all of these cost for our calculation with direct labor cots. At that point, your lead generation campaigns are now operating very similar to ecommerce campaigns. You’re optimizing for all stages and Bookkeeping for Painters working to hit a profitability metric for your lead generation business based on how far somebody gets in the buyer funnel and ideally all the way through to the customer stage. If you’re leveraging smart bidding, Google can optimize to a higher profitability level by generating leads for the ebook at a low cost per lead since the likelihood of a customer is low.

Prime Costs: Definition, Formula, Explanation, and Example

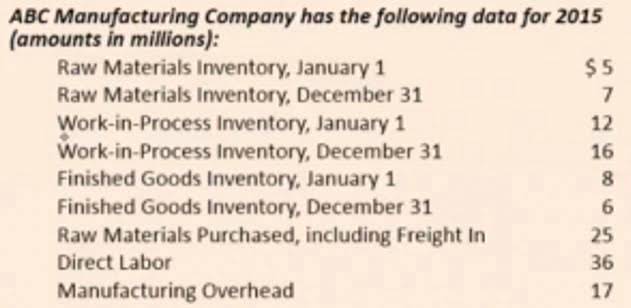

Bruce’s Bike Company is a bicycle manufacturer that specializes in high-end 10-speed bikes. Bruce is trying to figure out what his conversion costs are for the quarter in order to estimate his finished inventory for the interim financial statements. Conversion costs are the costs that are incurred by manufacturing companies when converting raw materials into finished goods. Therefore, it can be seen that the main premise of calculating conversion costs is to ensure that organizations are able to estimate the amount of input (in financial terms) that is required to bring the inventory to a finished state. Numerous manufacturing overhead costs are encountered in manufacturing facilities and processes.

How to add values to conversions in Google Ads

All of these will be calculated in the same way that you would calculate a normal conversion rate in your Google Ads account. If you’re in either one of these buckets or some combination of both, using conversion values in your Google ad account will be a highly valuable tool for you to see the best performance you can from your campaigns. Assume that there was no work in process inventory at the beginning and at the end of the accounting period.

How to Calculate the Average Cost of Converting One Unit of Product?

Conversion costs include direct labor and manufacturing overhead, such as electricity, rent, depreciation, and indirect materials. Conversion costs are important for cost accounting and management because they help to measure the efficiency and profitability of the production process. They also help to allocate the costs of goods sold (COGS) and inventory valuation. In accounting, conversion costs represent the money spent on turning raw materials into finished products. This includes wages for workers (direct labor costs) and other production expenses (manufacturing overhead costs). The Conversion Cost Calculator is an essential tool for manufacturers looking to accurately assess conversion costs their production costs.